WANT TO STREAMLINE PRODUCTION COSTS AND TIMELINES?

Specialised Rubber Mouldings That Lower Production Costs – Without Compromising Quality

Our extensive product range and capabilities include rubber O-rings, washers, seals, rubber gaskets, diaphragms, droppers, silicone tubing, fabric reinforced, overmoulded and multi material parts, extrusions, general rubber mouldings and customised products.

EXPLOREGet A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Get A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Key clients

Overview

First class technical, quality and operational systems ensure that the high quality product specified at onset, is continued to be produced and supplied for years to come.

Gulf Rubber Australia GRA are amongst Australia’s leading rubber and plastics manufacturing company. No other company is better placed to solve your current rubber mouldings supply issue. Depending on your product development journey, you could be looking for a specification that already sits in our stock portfolio. Great news if it is. If not, then we can custom engineer a bespoke solution as we specialise in concept to delivery project management of specialist component parts. If you need something that doesn’t exist, we can create it for you, cost-effectively and of the highest quality.

Benefits of Gulf Rubber's Rubber Mouldings

Technical Support

Quality Control

Potable Water Certifications

Long Term Repeatability

Cost Competitive

ISO 9001 Certified

Applications

- Water Industry – Potable and Non-potable

- Oil and Gas

- Appliance

- Medical

- Valves

- Industrial

- Construction

- Mining

- Automotive

- Electrical

- Agriculture

Gulf Rubber Design And Manufacture Industry Leading Products You Can Rely On

We supply specialised compression and injection rubber and plastic components to leaders in automotive, mining, construction, water, and other industries. With 40+ years’ experience, we’re experts in highly technical and critical OEM applications. We can design, manufacture, and deliver the highest quality products to suit your requirements.

Our focus areas

Rubber Mouldings

Includes both general and bespoke parts which are designed specific to application, with customisable dimensions, material choice and industry certifications.

Gulf offers an extensive range of standard industry size rubber O-Rings, in a wide range of polymer materials, ranging from EPDM, NBR, Viton FKM, Silicone and many more.

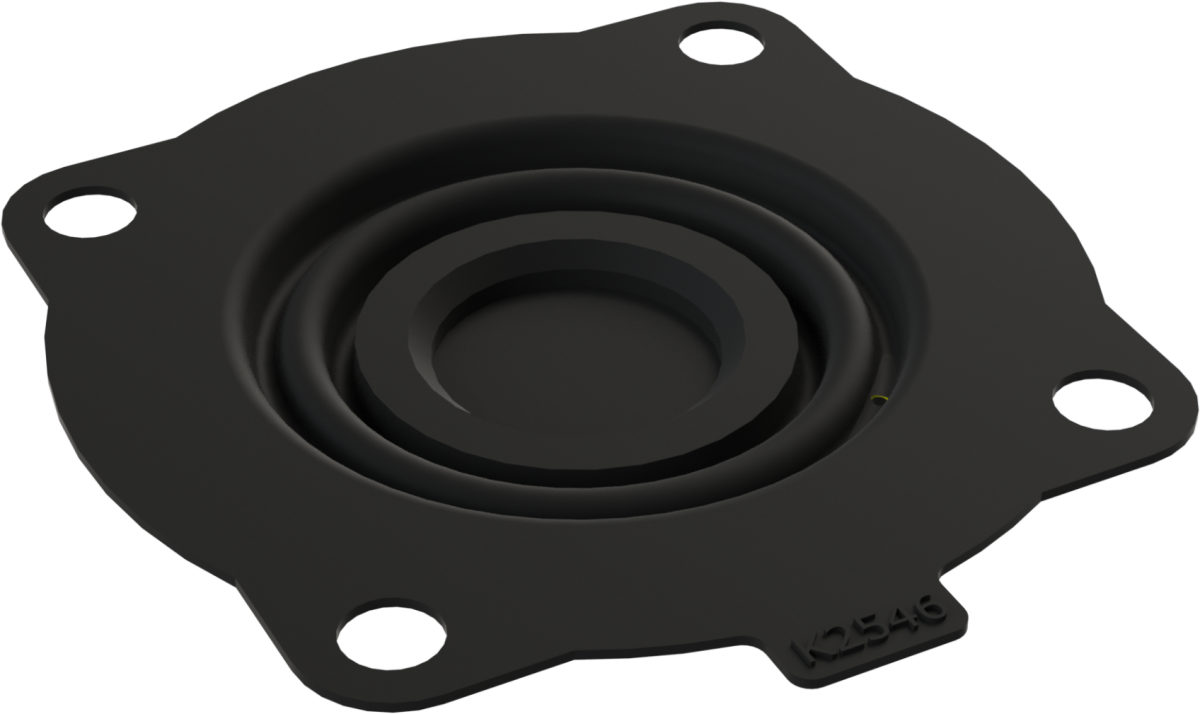

Diaphragms

From silicone diaphragms with exceptionally tight tolerances used in agricultural water drippers, to fabric reinforced rubbers and parts with dynamic function, Gulf draws on extensive experience and capabilities to provide superior part performance.

Custom Parts

Development, production and supply of rubber parts that are specific to the application of original equipment manufacturers. These parts typically have unique dimensions, tight tolerances, specific material properties and industry required certifications.

Integrated Components

Gulf manufactures integrated components, supplying complete sub-assemblies to streamline your production and simplify procurement. Inter-material bonding (of rubber, plastic, metal and fabric) and overmoulding provide for improved performance, a reduced number of components and reduced assembly.

A Million Shapes, Sizes and Purposes: Rubber Mouldings

One of the great satisfactions of being in the Australian rubber manufacturing industry is keeping customers happy. Once you’ve established your reputation for one specific project or part, people start to think of you for other items along the same lines, and the challenge is to catch anything they throw at you and make it to the required standard.

That’s what happened to us at Gulf Rubber. When we started out in 1980, we were simply in the industrial rubber business, but as word spread in various industries about the excellent material production and the versatility of the material in different applications, the requests started to flood in, and we found ourselves diversifying. We went from rubber merchants to specialised rubber mouldings suppliers and manufacturers – and to this day, we are continually open and looking for new ideas. Read More

Perhaps the simplest of rubber products is the O-Ring, which may be elementary in design, serves a multitude of purposes. Most importantly, it can be made of virtually any type of rubber or plastic and the trick is to use the right one for the job. This can take some discussion between a customer and our rubber engineers, outlining various options and their advantages and disadvantages. It’s a process we enjoy, because we like to be challenged and pride ourselves in our ability to come up with the perfect product, even if a customer isn’t 100% sure of what they needed when they initially approached us.

On the subject of variety, our range of rubber mouldings runs from washers to all kinds of rubber seals, industrial gaskets, diaphragms, droppers, silicon tubing and fabric-reinforced over-moulded and multi-material parts. We’re skilled at extrusions and general rubber mouldings as well as injection moulding in Brisbane, Sydney and Melbourne. We are able to customise standard items to suit a particular use.

If we haven’t made it before, that’s not a problem, it’s a challenge. We are a specialised rubber moulding supplier and whatever you ask for in our field, we’ll apply ourselves to the task and give you exactly what you need. Read Less

Quality Assurance

It’s our goal to ensure you never experience production downtime, expensive repairs, or frustrating warranty claims. That’s why all Gulf factories around the world, and all third-party factories that supply to Gulf, meet the quality standards required for ISO 9001 or IATF 16949.

Our products are manufactured to precise specifications with tight tolerances. When you partner with Gulf, you can have complete peace of mind knowing you will always receive the highest quality components.

Custom Design Capability

At Gulf, we thrive on the opportunity to innovate. If you need a custom product or solution, then our trusted engineers, chemists, and technologists will work tirelessly to deliver above and beyond your expectations. Whatever your specifications or requirements, you can rest easy knowing that you’ve got the strategic rubber manufacturer Australian partner who can solve the problem.

Searching for the right partner to solve your problem?

Book a consultation with our engineering team

Since 1980, Gulf Rubber’s specialised rubber and plastic engineers have designed bespoke, technical solutions for our partners across the globe. If you have a problem you can’t solve, a concept you can’t pinpoint, or a fragmented process you wish to simplify, we can help.

We’ll get to know your product and application, design a new solution, and use our experience to improve your business outcomes.