LOWER PRODUCTION COSTS WITHOUT COMPROMISING PERFORMANCE WITH GULF RUBBER

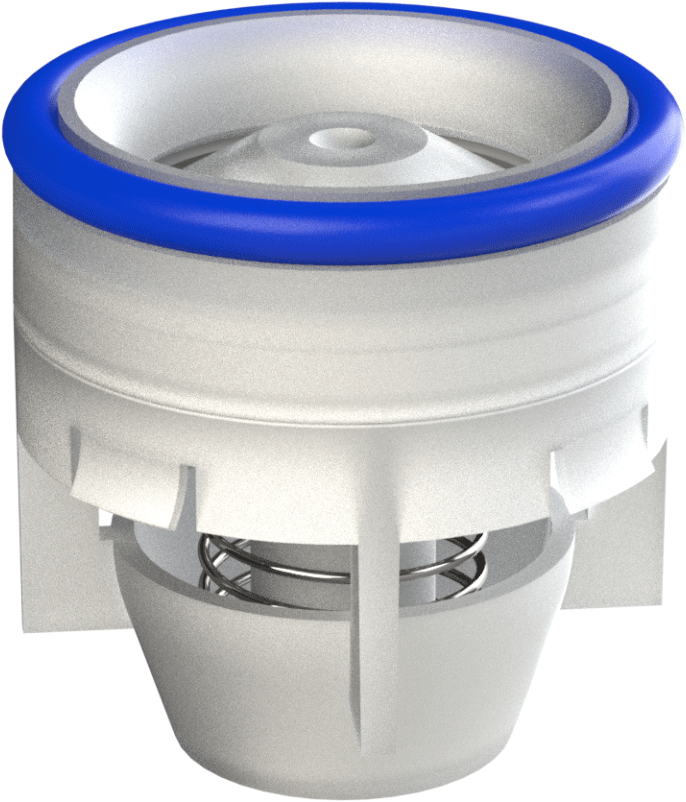

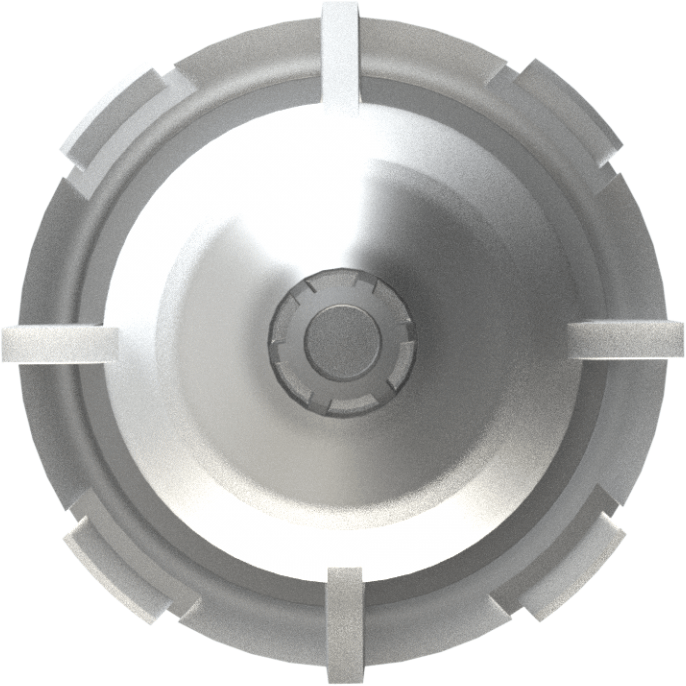

Premium-Quality Check Valves

Whether you need standard parts or a bespoke solution, we design and manufacture industry-leading check valves you can depend on – and we do it in an efficient manner that keeps you on time and inside budget.

Get A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Get A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Key clients

Overview

Check valves are non-return valves that allow the flow of fluid or gas in a certain direction but prevent reverse-flow in the opposite direction.

This is an essential requirement in water meters, allowing delivery of fresh water to households whilst preventing reverse-flow and potential contamination of the potable water mains supply.

Gulf manufactures a range of check valves and can design a bespoke new part specific to your requirement.

The many variables possible include outside diameter (typically 8mm to 50mm), length, material choice, opening pressure, whether a single or dual check valve and options such as snap fit. These factors are considered during the design process, taking into account the housing, application and operational conditions.

Gulf, as a supplier of check valves, is experienced in meeting and achieving required industry certifications. Such as AS4020:2018 and AS2845.1.

Our Check Valve Supplies

Benefits

Potable Water Certifications

Functional Certifications

100% Testing

Fully Customisable

Low Headloss

Ease of Insertion

Applications

- Water and Gas meters

- Tapware and valves

- Solenoid valves

- Pumps

- Irrigation

- Pressure relief and waste-water systems

Key Partners

International Certifications

Gulf Rubber Design And Manufacture Industry Leading Products You Can Rely On

We supply specialised compression and injection rubber and plastic components to leaders in automotive, mining, construction, water, and other industries. With 40+ years’ experience, we’re experts in highly technical and critical OEM applications. We can design, manufacture, and deliver the highest quality products to suit your requirements.

Quality Assurance

It’s our goal to ensure you never experience production downtime, expensive repairs, or frustrating warranty claims. That’s why all Gulf factories around the world, and all third-party factories that supply to Gulf, meet the quality standards required for ISO 9001 or IATF 16949.

Our products are manufactured to precise specifications with tight tolerances. When you partner with Gulf, you can have complete peace of mind knowing you will always receive the highest quality components.

Custom Design Capability

At Gulf, we thrive on the opportunity to innovate. If you need a custom product or solution, then our trusted engineers, chemists, and technologists will work tirelessly to deliver above and beyond your expectations. Whatever your specifications or requirements, you can rest easy knowing that you’ve got the strategic partner who can solve the problem.

Control Liquid Flow with a Check Valve Manufacturer in Australia

Check valves are essential components for many industries that pump fluids. These can include water supply, waste water treatment, oil refineries, processing plants and HVAC systems for large buildings where coolant is pumped to high floors.

Check valves are installed to prevent backflow that can cause contamination but to do so in a way that prevents water hammer that can result in damage to equipment. Water hammer occurs when a liquid stops being pumped up a pipe, causing it to fall back so the check valve stops the flow instantly. The resulting surge causes loud noises as the pipe stretches and can lead to considerable damage. Choosing correctly from an Australian check valve supplier such as Gulf Rubber means you can avoid these problems and control liquid flows. Read More

Making Correct Choices from Check Valve Suppliers

Check valves are of different types with varying characteristics:

- Swing check valves are the most common type and have a disc mounted on a shaft. This is designed to permit forward flow but, when the flow reverses, the disc swings back onto a seat and blocks the flow.

- Ball check valves have a ball that moves up to allow liquid to flow and then down onto a seat to prevent reverse flow.

- Tilting disc check valves have a double-flanged body with a disc held in place by a shaft. The disc opens at low flow rates but closes due to gravity when the flow reverses. Slanted seat versions are available that are resistant to water hammer.

When choosing the type of valve you need, consider the following:

- the type of fluid being controlled; in particular, consider whether solids are present, such as in sewage treatment, which some check valves can’t handle

- the speed of liquid flow, since fast opening and closing of the check valve can cause surges

- head loss that can occur due to elevation differences and the frictional resistance of pipes

- characteristics of the valve, particularly its speed of closure that can prevent slamming that leads to system pressure surges

- cost of ownership that should take into account all costs (including maintenance and energy use) over the life of the check valve rather than simply its purchase price.

Science Meets Manufacturing Expertise: Check Valves in Melbourne

The majority of people have no idea of what a check valve is – and they don’t need to. It’s one of those things that only really interests the experts who use them and manufacturers who supply them. As an industry insider, you understand the importance of being able to source check valves in Australia, in the wider APAC region, and everywhere else, for that matter, but it’s your neck of the woods that matters to you. You need to know where you can get them, you need to be sure they’re of the highest quality, and you need to be able to get your hands on them quickly.

That’s where we come in. We at Gulf Rubber make and supply top-notch check valves in Melbourne. We are the leading valve manufacturers and suppliers in these parts, and we are dedicated to playing our part in our customers’ success by not only supplying the best valves but also achieving quick and timely deliveries. We understand that production of entire units and systems can’t be held up for the lack of check valves in Australia: Business must go on in a professional manner and we want to help you to do that.

When check valves are used in the potable water business, it is essential they do the job they’re designed to do, otherwise public health could be in danger. Therefore, you need a valve manufacturer that takes the business very seriously and operates to the highest standard, as you do. That’s us in a nutshell. We manufacture and supply check valves in Australia and further afield – and we do it in a timely fashion, so you can stay on schedule and keep the orders – and the payments – flowing as smoothly as the water.

If you need check valves suppliers, contact us and we’ll get you the best – and we’ll get them to you promptly.

Check Valves Supplys that Work Well and Reliably

Price should never be the most important consideration when choosing check valves. As a leading check valve manufacturer, we do endeavour to supply parts that are competitively priced and cost-effective. But the main aim is to provide you with something that works effectively and reliably for a long time so you have no concerns about its performance including our rubber o-rings supply and automotive engineering services.

We can supply standard check valves or design and manufacture bespoke versions that will be perfect for your particular application. Either way, we can supply valves that will stop liquid flows, prevent harmful backflows and reduce slamming and water hammer that can cause damage. Get in touch to let us know your requirements and we’ll provide exactly the check valves or rubber gaskets you need. With a combination of our industry knowledge, high-quality manufacturing, extensive quality control and attention to detail, you’ll gain full control of your fluid flows. Read Less

Related Products

Searching for the right partner to solve your problem?

Book a consultation with our engineering team

Since 1980, Gulf Rubber’s specialised rubber and plastic engineers have designed bespoke, technical solutions for our partners across the globe. If you have a problem you can’t solve, a concept you can’t pinpoint, or a fragmented process you wish to simplify, we can help.

We’ll get to know your product and application, design a new solution, and use our experience to improve your business outcomes.