Injection Moulding in Melbourne

Gulf specialises in engineered plastic components for critical applications that demand tight tolerances, reliable quality control, and long term production repeatability. We offer an extensive range of products across the automotive, industrial, agriculture, tapware, and general potable and non-potable water industries.

Enquire Now EXPLOREOverview

We offer an extensive range of products across the automotive, industrial, agriculture, tapware, and general potable and non-potable water industries.

Utilising our material science expertise, we work with Customers to understand their projects and challenges and develop suitable material solutions. We use a variety of plastics from nylon 4, 6 or 6/6, polypropylene, TPV’s (such as santoprene), acetal, noryl, blends of Nylon with glass or PTFE, nylon/kevlar cord, PE foam, EVA foam and others.

Gulf understands that designing plastic components and composites with plastic materials require both linear and non-linear stress analysis, for function, fitment and durability. Gulf uses state of the art design software to ensure product design and performance is predicted and optimised at the design stage on any product.

In addition to the plastic material knowledge, we also design and manufacture plastic tooling in house, offer rapid prototype capability for all services including injection moulding Melbourne services. Read More

Benefits

In-house toolmaking

Rapid prototyping

Quality Assurance

Material expertise

Customised design offering

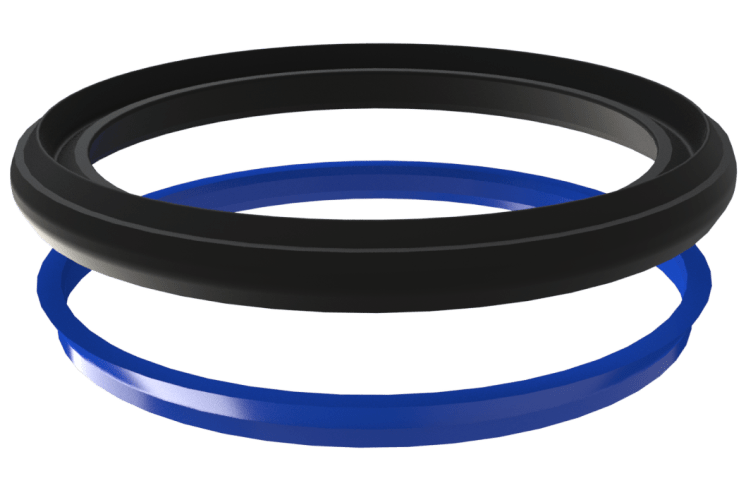

Range

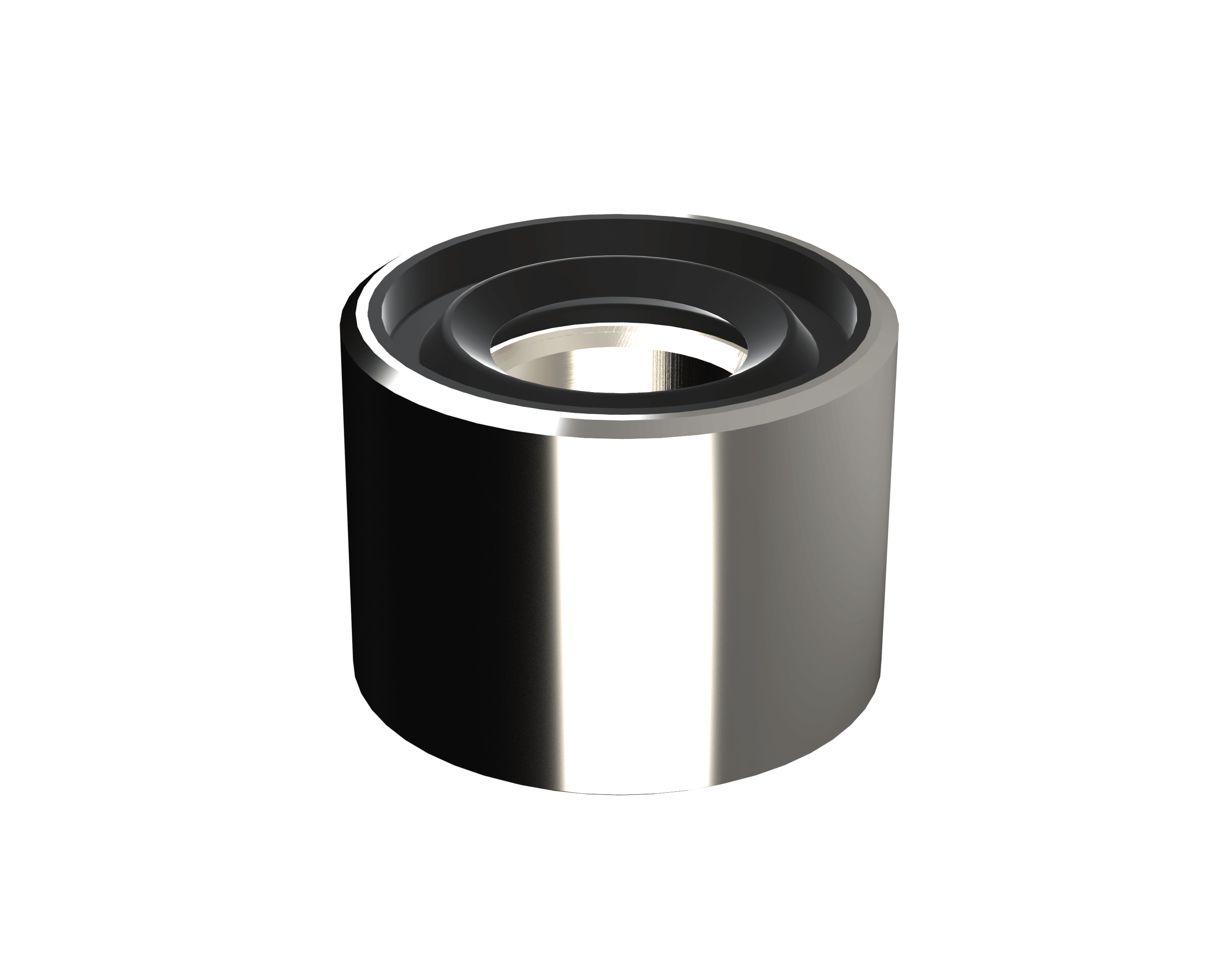

Centering Bush

Critical OEM component used to center and maintain radial position of the vehicle propshaft.

Are you Looking for Plastic Injection Moulding in Melbourne?

Melbourne injection moulding demands has increased notably in recent years. More companies are turning to Australia-based and local specialists to create and supply their plastic component parts. Injection moulding Australia is a relatively easy process used to shape plastic for all types of applications. Almost all shaped plastic goes through this process. The process can be traced back to the 1870s and was particularly successful in the button and comb manufacturing industries.

If you are looking for custom plastic moulding in Melbourne, then take a closer look at Gulf Rubber Australia (GRA) we are one of the leading specialists in engineered plastic and rubber.

Melbourne Custom Plastic Moulding Services

If you are in manufacturing and have found yourself needing a plastic component part. Rest assured, we have the team to deliver it for you. Our clients fall into one of two distinct categories. The first is the repeat customer, who needs a steady flow of new plastic parts manufacturing or industrial rubber manufacturers for different products and applications. The second type of client is the one-off company that needs something simple and specific and requires a lot of them. Whichever category you fall into, we can deliver your plastic moulding here in Melbourne. Our services can be an all-encompassing commission to cover your project from design through to delivery or a bespoke package of functions if you already have some preparation completed. No matter what your circumstances are or where you need injection moulding services in Australia, we can pick up and complete the job for you.

Plastic Mould Manufacturing in Melbourne

The production of a plastic part through injection moulding is a multifaceted schedule of activities, ending up with a perfectly formed part ready to go straight into use. Many parts of the program can be undertaken locally in Melbourne. Depending on the type of part, the quantities required and the delivery timeline, parts of the project may be farmed out to laboratories and factories elsewhere but you can definitely request for injection moulding in Sydney or if you’re looking for injection moulding in Brisbane.

Gulf has been established for over 40 years and has a wealth of in-house professional experience including chemists, engineers and quality managers. We use state-of-the-art facilities for research and development. Our processes include rigorous analysis and testing of all products we manufacture from o-ring mouldings to rubber gasket manufacturing. We offer fast and cost-effective design services and apply specialist know-how to ensure parts perform to maximum efficiency. We also ensure any new part is compatible with other integrated components and is capable of bonding against other materials. The Gulf plastic and rubber engineering service offering is a complete suite of professional product development services.

The Importance of Being Precise: A Plastic Moulding Manufacturer in Melbourne

As in any area of manufacturing, all companies are not equal. That’s why, if you are a discriminating member of your industry and need a plastic moulding manufacturer in Melbourne, you are constantly looking for the best. And that means the best materials and a leading manufacturer that uses those materials.

Precision is a keyword here, because tolerances can be minimal and even the latest materials can be wasted if the product doesn’t come out in the precise form it should. This is essential in moulded plastics and this accuracy is what makes our products sought after in areas from the automotive rubber manufacturers industry and construction to mining and water.

We are constantly monitoring developments in the plastics industry and adopting only the best, the most appropriate for the customers who trust our choices. From that basis – the right materials in terms of function and durability – we proceed through state-of-the-art design software to highly demanding precision manufacturing and unforgiving quality control for the products that come through our warehouse.

And one other thing: we are aware that when a customer using plastic moulding Melbourne services or elsewhere needs something, they need it now, so we are determined to deliver our products in good time. We want to contribute to your reputation for doing a great job and getting it done on schedule.

Start the Process – Get in Touch Today

It is highly likely that you are now considering Gulf for a quotation for your plastic injection moulding project in Melbourne. We offer a no-obligation strategic review of your needs. It’s an engineering-based discussion and we’d be happy to arrange this for you at your earliest convenience. In the first instance please call us on 02 8723 6100. Alternatively, you could give a little more detail by completing our online contact form. Once received, one of the team will contact you and arrange a call. Read Less

Custom Design Capability

At Gulf, we thrive on the opportunity to innovate. If you need a custom product or solution, then our trusted engineers, chemists, and technologists will work tirelessly to deliver above and beyond your expectations. Whatever your specifications or requirements, you can rest easy knowing that you’ve got the strategic partner who can solve the problem.

Quality Assurance

It’s our goal to ensure you never experience production downtime, expensive repairs, or frustrating warranty claims. That’s why all Gulf factories around the world, and all third-party factories that supply to Gulf, meet the quality standards required for ISO 9001 or IATF 16949.

Our products are manufactured to precise specifications with tight tolerances. When you partner with Gulf, you can have complete peace of mind knowing you will always receive the highest quality components.

Related Products

Searching for the right partner to solve your problem?

Book a consultation with our engineering team

Since 1980, Gulf Rubber’s specialised rubber and plastic engineers have designed bespoke, technical solutions for our partners across the globe. If you have a problem you can’t solve, a concept you can’t pinpoint, or a fragmented process you wish to simplify, we can help.

We’ll get to know your product and application, design a new solution, and use our experience to improve your business outcomes.