Rubber O-Rings

Our extensive product range and capabilities include large diameter o-rings, O-rings manufacturing, washers, seals, gaskets, diaphragms, droppers, silicone tubing, fabric reinforced, overmoulded and multi-material parts, extrusions, general mouldings and customised products.

Enquire Now EXPLOREOverview

First class technical, quality and operational systems ensure that the high quality product specified at onset, is continued to be produced and supplied for years to come.

Gulf Rubber Australia GRA are amongst Australia’s leading rubber and plastics manufacturing company. No other company is better placed to solve your current large o-ring supply issue. Depending on your product development journey, you could be looking for a specification that already sits in our stock portfolio. Great news if it is. If not, then we can custom engineer a bespoke solution as we specialise in concept to delivery project management of specialist component parts. If you need something that doesn’t exist, we can create it for you, cost-effectively and of the highest quality from the best sealing ring manufacturer. Read More

Benefits of Gulf Rubber's Rubber O-Rings

Technical Support

Quality Control

Potable Water Certifications

Long Term Repeatability

Cost Competitive

ISO 9001 Certified

Applications

- Water Industry – Potable and Non-potable

- Oil and Gas

- Appliance

- Medical

- Valves

- Industrial

- Construction

- Mining

- Automotive

- Electrical

- Agriculture

Our focus areas

Rubber O-Rings

Includes both general and bespoke parts which are designed specific to application, with customisable dimensions, material choice and industry certifications.

Gulf offers an extensive range of standard industry size O-Rings, in a wide range of polymer materials, ranging from EPDM, NBR, Viton FKM, Silicone and many more.

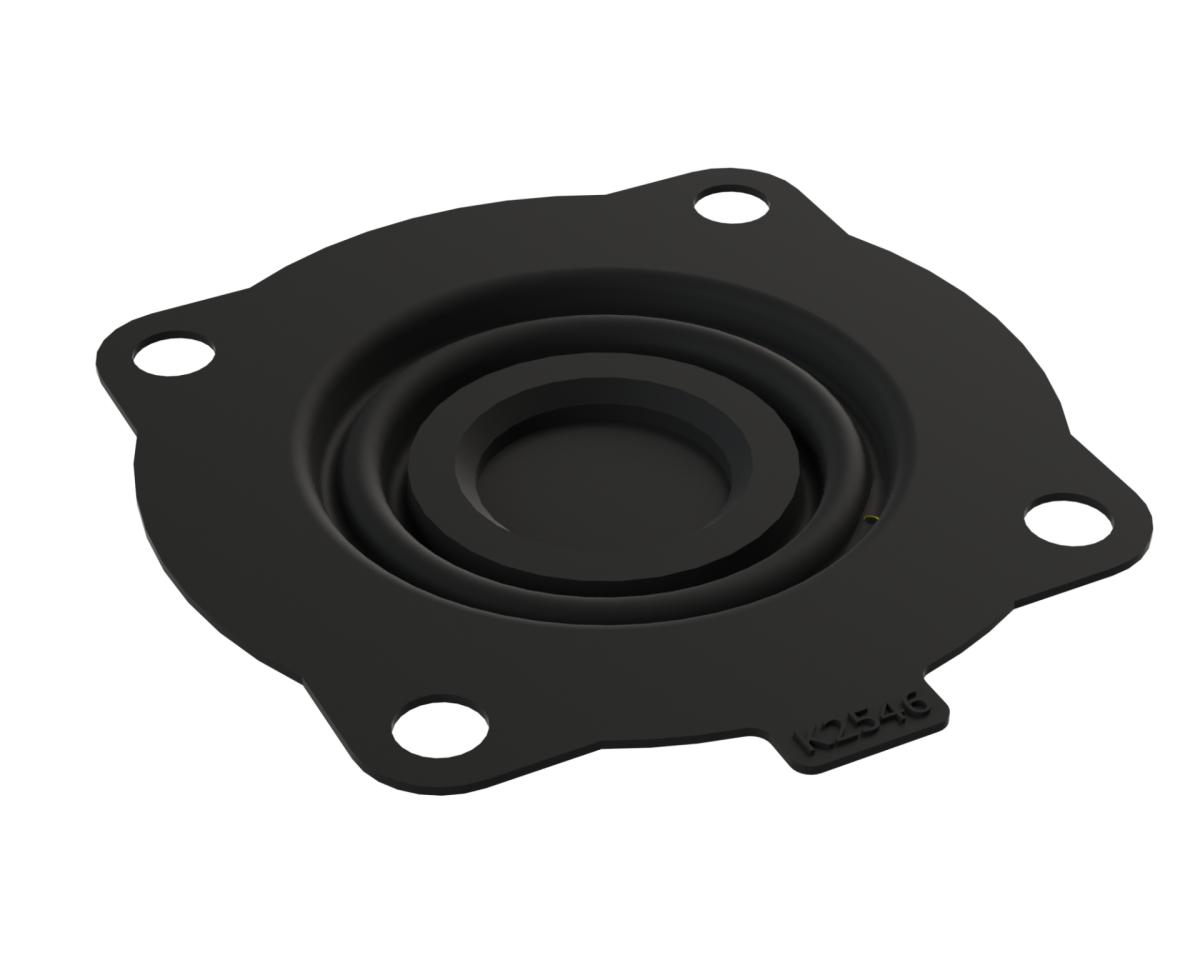

Diaphragms

From silicone diaphragms with exceptionally tight tolerances used in agricultural water drippers, to fabric reinforced rubbers and parts with dynamic function, Gulf draws on extensive experience and capabilities to provide superior part performance.

Custom Parts

Development, production and supply of rubber parts that are specific to the application of original equipment manufacturers. These parts typically have unique dimensions, tight tolerances, specific material properties and industry required certifications.

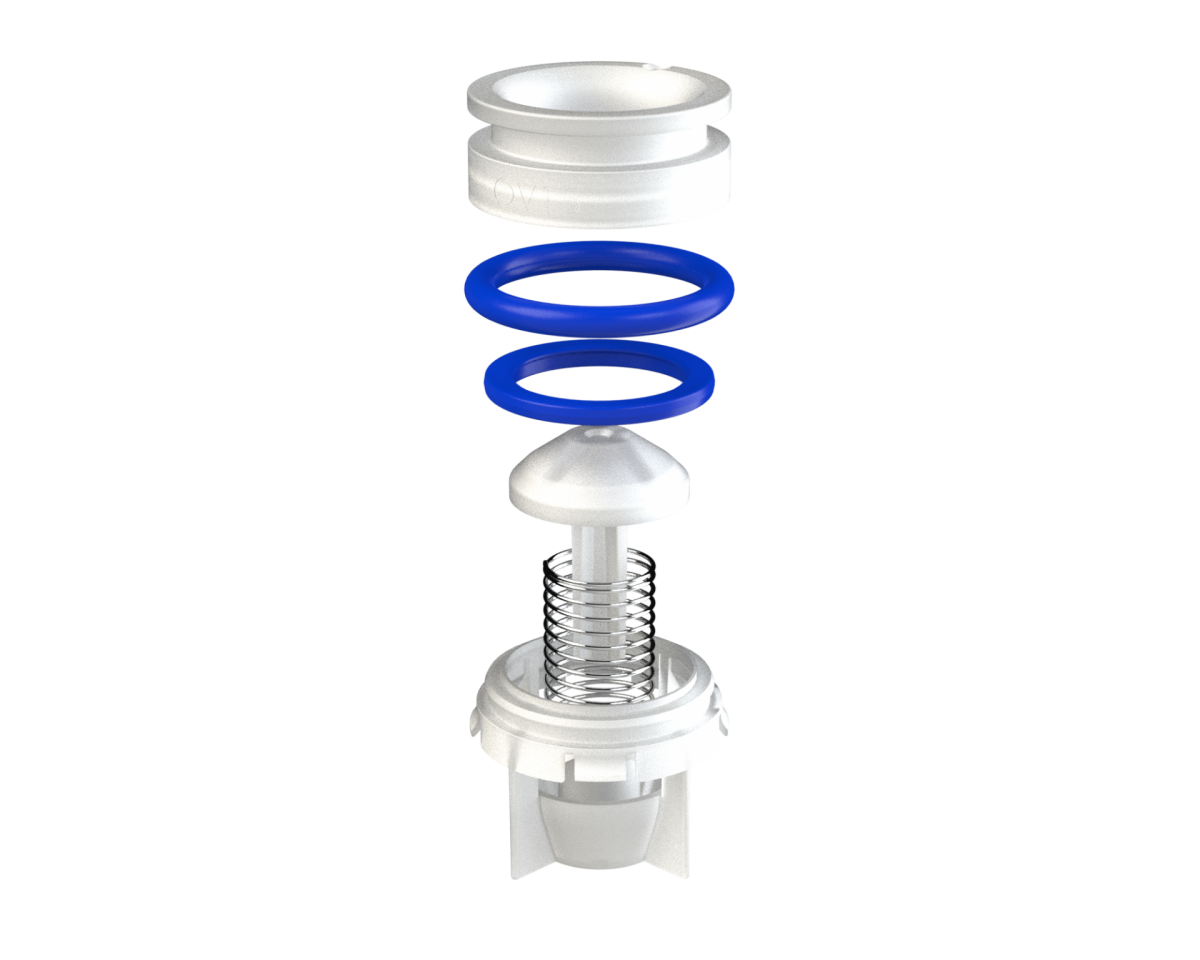

Integrated Components

Gulf manufactures integrated components, supplying complete sub-assemblies to streamline your production and simplify procurement. Inter-material bonding (of rubber, plastic, metal and fabric) and overmoulding provide for improved performance, a reduced number of components and reduced assembly

Searching for Large Industrial Rubber O-Rings? We are Australia’s Leading Supplier

Gulf Rubber Australia (GRA) lead the way in the production of rubber and plastic component parts, including industrial o-rings for large applications. It could be that the specification you require is a stock item and the supply is then straightforward and completed quite quickly. It may also be the case that the rubber o-ring you are looking for is for something new and needs to be created, perhaps a large diameter rubber o-ring, then we offer a design to delivery project management service where we can create the part for you efficiently and cost-effectively.

GRA are Premier Industrial Large Rubber O-Ring for Very Good Reasons

Manufacturing excellence is the key trait that makes GRA the go-to industrial rubber o-ring supplier in Australia. There are a handful of notable reasons why we stand head and shoulders above others in this sector of rubber manufacturing in Australia.

GRA’s track record is exemplary with a long history of repeated high performance. Within the production process, there’s a strong element of testing, covering heat ageing, chloramine resistance and stress relaxation analysis. We are also skilled in the use of a large range of materials, not just rubber and injection moulding in Australia. Zero-defect scrutiny via an automated inspection process produces a zero-defect status. Finally, we are accredited with international standards of quality, ISO 9001 and QS 9000. We also work to IATF 16949.

These elements are at the core of past success and have supported a level of manufacturing excellence unrivaled in the Australian rubber engineering industry.

Leading O-Ring Seal Supplier

Gulf Rubber Australia GRA are amongst Australia’s leading rubber and plastics manufacturing company. No other company is better placed to solve your current seal o-ring supplier issue. Depending on your product development journey, you could be looking for a specification that already sits in our stock portfolio. Great news if it is. If not, then we can custom engineer a bespoke solution as we specialise in concept to delivery project management of specialist component parts. If you need something that doesn’t exist, we can create it for you, cost-effectively and to the highest quality.

What Makes the GRA Premier Custom Rubber O-Ring Manufacturers?

There are five areas of manufacturing excellence that make GRA a stand-out sealing ring manufacturer.

- Proven past performance – GRA works to low tolerances and guaranteed material properties. This can only be achieved through accurate design, precise manufacturing and strong product analysis.

- Robust testing – our seal O-rings supplier tests the products for long-term performance. This process includes stress relaxation, heat ageing and chloramine resistance testing.

- Large range of materials – O-rings can be manufactured from a vast range of materials and even customised to meet any specific product application.

- Zero defect assurances – all manufacturing is subject to automated inspection to guarantee a zero-defect status, essential for all critical applications.

- International standards – all GRA manufactured rubber rings meet a vast range, including all the major international standards and follow a set of manufacturing processes that are ISO 9000 and QS 9000 certified.

Unrivalled Service Approach from Industry Respected Rubber O-Ring Wholesaler

Most of our new clients come to us by way of personal introductions and recommendations. Technical Directors looking for specific results, tend to trust industry acquaintances for quality introductions. This is particularly true for several of our clients who searched for seal rubber o-ring suppliers for all purposes including automotive rubber manufacturing.

The process of being considered to supply or manufacture custom o-rings for a client follows the same first step. A meeting to determine the needs and ambitions of the client. We find this is best approached at a technical level so that the component specification takes centre stage, followed by the customer support mechanisms we put into our project management planning.

By the end of the first consultation, we’ve usually found all the required common ground to make the sealing o-ring supply and /or manufacturing a real prospect. We believe the best results come through close consultation and timely project management.

A Formidable Large Diameter Rubber O-Ring Service Offering

Most of our new clients come to us by way of personal introductions and recommendations. Technical Directors looking for specific results, tend to trust industry acquaintances for quality introductions. This is particularly true for several of our clients who searched for industrial o-ring manufacturers for all purposes including automotive rubber manufacturing.

By adopting a transparent partnership approach, we find our clients are much more settled in the project management path that we utilise and agree upon. This is because all progress is monitored, reviewed and shared regularly to ensure timely delivery and on-point budgeting is maintained. We don’t believe in surprises when it comes to project management.

The process of being considered to supply or manufacture custom o-rings for a client follows the same first step. A meeting to determine the needs and ambitions of the client. We find this is best approached at a technical level so that the component specification takes centre stage, followed by the customer support mechanisms we put into our project management planning.

By the end of the first consultation, we’ve usually found all the required common ground to make the rubber o-rings wholesale supply and /or manufacturing a real prospect. We believe the best results come through close consultation and timely project management.

We have a customer service focus which has won the company impressive blue-chip contracts with global giants such as Daimler Benz, Dupont and BMW.

Rubber Seal Ring: High Quality O-Rings in Australia

There comes a time in a person’s life when they suddenly need to know where they can get o-rings in Australia. It’s not an everyday occurrence, unless they are in something like the automotive industry, but when it happens and they’re frantically looking up o-rings suppliers near me, they may well find themselves contacting Gulf Rubber.

We are a leading manufacturer of rubber and plastic components, which we supply to, and make, for not just the automotive world but the mining, construction and water industries. These are all disciplines where excellence is essential, not just in materials used but in the precision of their manufacture, because when you’re dealing with seals, tolerances are very small, you’ve got to hit the nail on the head every time.

As manufacturers rather than solely suppliers of rubber seal rings, we can provide customers with large o-rings or in fact any size they need. We, Gulf Rubber, are custom o-ring suppliers, what you need, Gulf can provide.

Once a client joins us , there is no longer a need to go back to googling o-ring suppliers Australia, because we manufacture and supply the best quality there is.

Why Choosing Good Company Matters

When it comes to finding a large o-ring manufacturer for precision engineered rubber and plastic components, there are plenty of options but it’s important to remember that not all manufacturers produce the same quality. Working with a professional company can make all the difference in the quality of your products and your overall experience.

Firstly, professional automotive rubber manufacturers will have years of experience and expertise in their field. They will have developed tried-and-tested processes for creating high-quality components, ensuring that you receive reliable and consistent results every time. Additionally, they will have access to state-of-the-art equipment and technology that allows them to produce even the most complex designs with precision and accuracy.

Finally, working with a company that offers professional rubber engineering services means you can expect exceptional customer service from start to finish. They will take the time to understand your specific needs and requirements, providing guidance throughout the design process to ensure that your components meet all necessary specifications.

So where can you find a Custom O-ring supplier that ticks all of those boxes? Right here. You’ll get the best quality products and customer service when you choose Gulf Rubber.

Get in Touch Today and Let’s Start Your Search for the Perfect Large Custom Industrial O-Ring

As a company, we prefer to start any new relationship with a no-obligation fact-finding review, to establish the goals and ambitions of the client. It could be that we have items in stock or moulds in storage that match the specifications required by our sealing ring manufacturer. In this scenario, costs and timeframes are considerably reduced and results are achieved relatively quickly. To start the process and to home in on your industrial large o-ring requirements, please call us at our Sydney head office on 02 8723 6100. Alternatively, you could give a little more detail by completing our online form. Once received, one of the team will contact you and arrange a first contact chat with one of our engineering team.

Quality Assurance

It’s our goal to ensure you never experience production downtime, expensive repairs, or frustrating warranty claims. That’s why all Gulf factories around the world, and all third-party factories that supply to Gulf, meet the quality standards required for ISO 9001 or IATF 16949.

Our products are manufactured to precise specifications with tight tolerances. When you partner with Gulf, you can have complete peace of mind knowing you will always receive the highest quality components.

Custom Design Capability

At Gulf, we thrive on the opportunity to innovate. If you need a custom product or solution, then our trusted engineers, chemists, and technologists will work tirelessly to deliver above and beyond your expectations. Whatever your specifications or requirements, you can rest easy knowing that you’ve got the strategic partner who can solve the problem.

Searching for the right partner to solve your problem?

Book a consultation with our engineering team

Since 1980, Gulf Rubber’s specialised rubber and plastic engineers have designed bespoke, technical solutions for our partners across the globe. If you have a problem you can’t solve, a concept you can’t pinpoint, or a fragmented process you wish to simplify, we can help.

We’ll get to know your product and application, design a new solution, and use our experience to improve your business outcomes.