NEED PARTS FOR THE AUTOMOTIVE, MINING, CONSTRUCTION OR WATER INDUSTRY?

Lower Production Costs Without Sacrificing Quality Using Our Specialised Plastic Components

Our plastic components are engineered to precise specifications with tight tolerances to ensure long-term production repeatability and world-class quality.

EXPLOREGet A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Get A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Key clients

Overview

Gulf specialises in engineered plastic components for critical applications that demand tight tolerances, reliable quality control, and long term production repeatability. We offer an extensive range of products across the automotive, industrial, agriculture, tapware, injection moulding and general potable and non-potable water industries.

Utilising our material science expertise, we work with Customers to understand their projects and challenges and develop suitable material solutions. We use a variety of plastics from nylon 4, 6 or 6/6, polypropylene, TPV’s (such as santoprene), acetal, noryl, blends of Nylon with glass or PTFE, nylon/kevlar cord, PE foam, EVA foam and others.

Gulf understands that designing plastic components and composites with plastic materials require both linear and non-linear stress analysis, for function, fitment and durability. Gulf uses state of the art design software to ensure product design and performance is predicted and optimised at the design stage on any product.

Benefits

In-house toolmaking

Rapid prototyping

Quality Assurance

Material expertise

Customised design offering

Gulf Rubber Design And Manufacture Industry Leading Products You Can Rely On

We supply specialised compression and injection rubber and plastic components to leaders in automotive, mining, construction, water, and other industries. With 40+ years’ experience, we’re experts in highly technical and critical OEM applications. We can design, manufacture, and deliver the highest quality products to suit your requirements.

Gallery

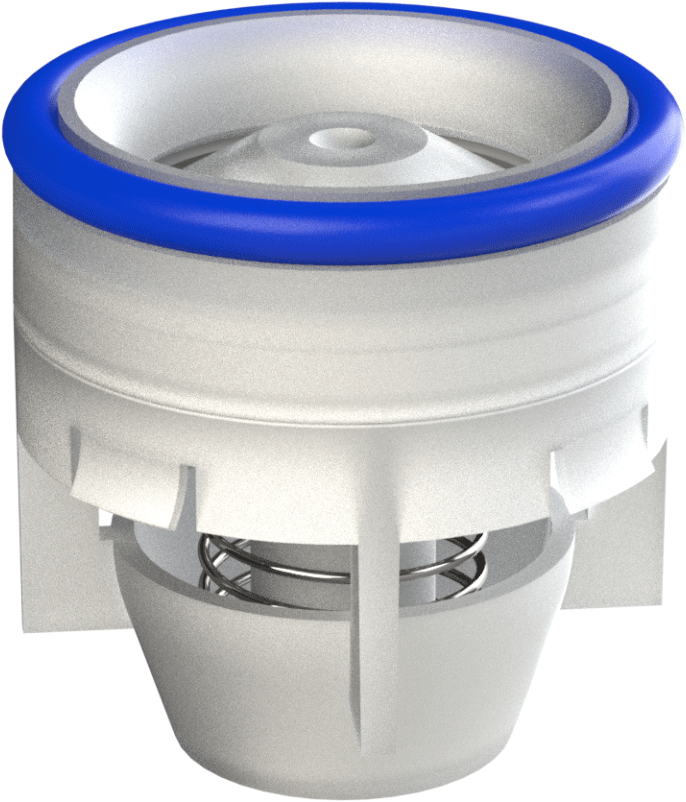

Check Valve

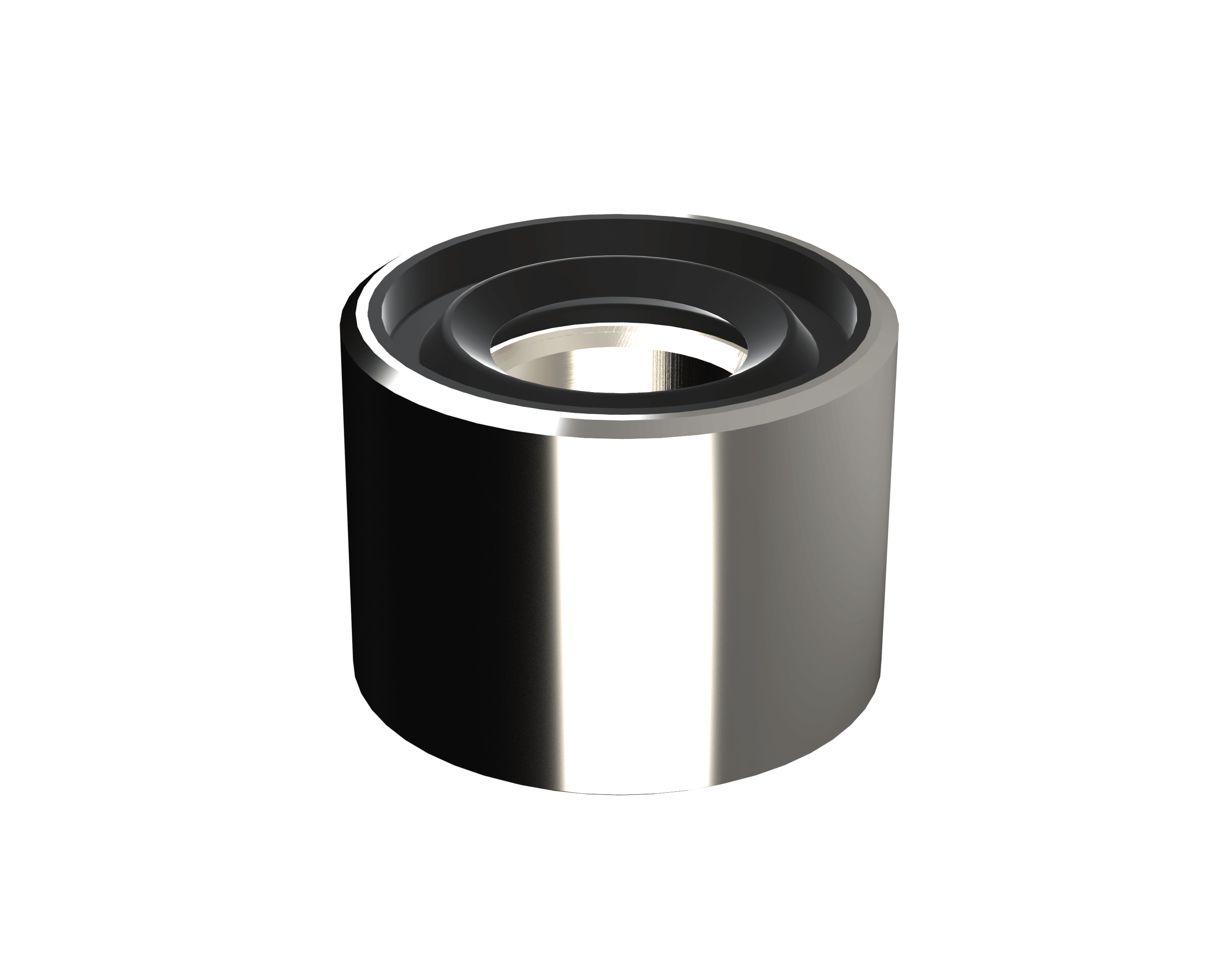

Centering Bush

Critical OEM component used to center and maintain radial position of the vehicle propshaft.

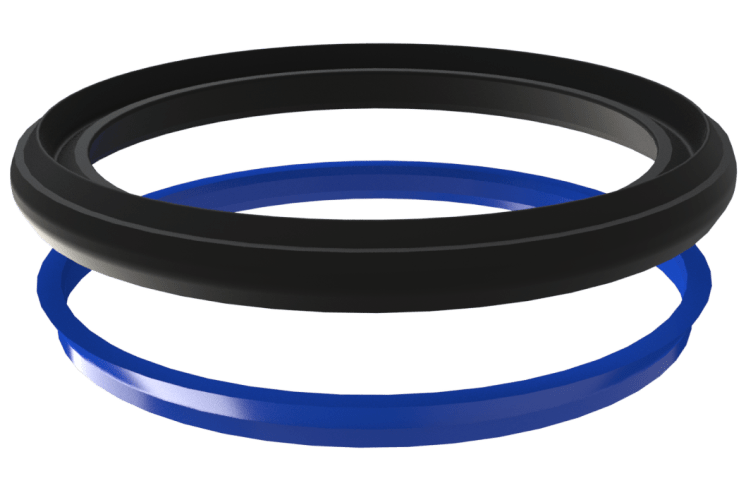

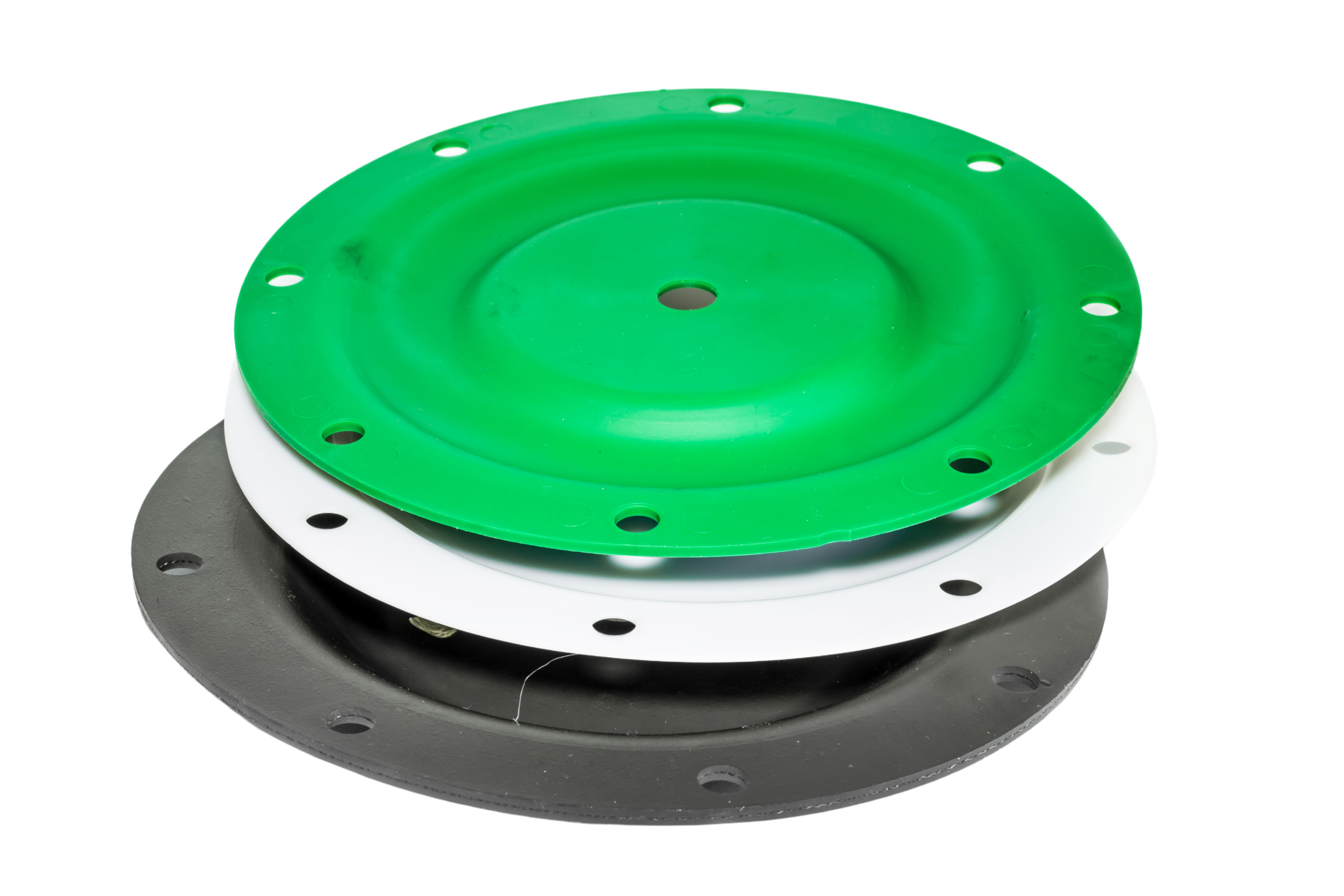

Diaphragms

From silicone diaphragms with exceptionally tight tolerances used in agricultural water drippers, to fabric reinforced rubbers and parts with dynamic function, Gulf draws on extensive experience and capabilities to provide superior part performance.

Quality Assurance

It’s our goal to ensure you never experience production downtime, expensive repairs, or frustrating warranty claims. That’s why all Gulf factories around the world, and all third-party factories that supply to Gulf, meet the quality standards required for ISO 9001 or IATF 16949.

Our products are manufactured to precise specifications with tight tolerances. When you partner with Gulf, you can have complete peace of mind knowing you will always receive the highest quality components.

Custom Design Capability

At Gulf, we thrive on the opportunity to innovate. If you need a custom product or solution, then our trusted engineers, chemists, industrial rubber manufacturers and technologists will work tirelessly to deliver above and beyond your expectations. Whatever your specifications or requirements, you can rest easy knowing that you’ve got the strategic partner who can solve the problem.

Related Products

Searching for the right partner to solve your problem?

Book a consultation with our engineering team

Since 1980, Gulf Rubber’s specialised rubber and plastic engineers have designed bespoke, technical solutions for our partners across the globe. If you have a problem you can’t solve, a concept you can’t pinpoint, or a fragmented process you wish to simplify, we can help.

We’ll get to know your product and application, design a new solution, and use our experience to improve your business outcomes.