Get A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Get A Free Quote

For product pricing, quote requests, technical information or project support simply fill out the form and our team will be in touch.

Key clients

OVERVIEW

Gaskets are essential components in mechanical and industrial applications, serving a critical role in preventing the leakage of fluids or gases between two or more surfaces. These components are vital in creating effective barriers that can endure extreme temperatures, pressures, and exposure to chemicals. In Australia, their application is widespread across various industries, including aerospace, automotive, construction, and healthcare, underscoring their importance in both everyday and specialised equipment.

Because most of these products are very different, at Gulf Rubber we specialise in designing, manufacturing and supplying custom-made rubber gaskets rather than being purely a gasket supplier. By doing this, we ensure that each industrial gasket that we deliver will do its job perfectly.

-

1

What type of Gasket are you looking for?

PVC Pipe and Fittings

Gulf gaskets are precision engineered to maintain their sealing performance for the life cycle of a pipe installation.

Ductile Iron Pipe and Fittings

All Gulf Rubber Pipe gaskets are SAI Global Standards Marked to AS16-46-2007, under Licence SMKP 20133.

Storm Water and Drainage

-

2

These are the products you can select from

Option 1PVC - O Pressure Pipe

Option 2PVC-M Pressure Pipe

Option 3PVC AS1260 Sewer

Option 4PVC Fittings

Option 1Ductile Iron Pipe

Option 2Ductile Iron Fittings

-

3

Recommended products

Gulf Rubber Design And Manufacture Industry Leading Products You Can Rely On

We supply specialised compression and injection rubber and plastic components to leaders in automotive, mining, construction, water, and other industries. With 40+ years’ experience, we’re experts in highly technical and critical OEM applications. We can design, manufacture, and deliver the highest quality products to suit your requirements.

Custom Solutions from an Industrial Gasket Supplier in Australia

Gaskets are very widely used in Australian industries such as oil and gas, power generation, aerospace, pharmaceuticals, automotive rubber components manufacturing and food processing.

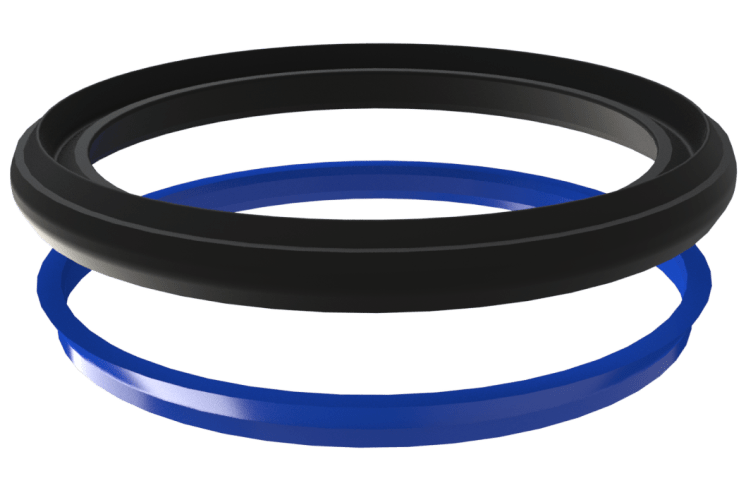

The very diversity of these industries means that gasket needs are very varied, and we have built up a lot of experience in successfully meeting the challenges that they present. Among the common types are O-rings, U-cups, D-rings, and flat gaskets, each tailored for specific sealing functions. The materials used in gasket manufacturing are chosen for their durability and resistance to challenging conditions. Silicone rubber, nitrile rubber, EPDM (ethylene propylene diene monomer), and fluoroelastomers (FKM) are some of the materials that stand out for their excellent resistance to heat aging, ozone degradation, and chemicals, ensuring the gaskets’ reliability in harsh environments.

At Gulf Rubber Australia, gasket manufacture is our business (part of our business, anyway). We certainly know all there is to know and we’d be happy to help you out. Our team is the best in the business and our goal is to ensure you experience no downtime when it comes to production. Gulf Rubber promises you’ll receive the best quality products without even a thought about not meeting the required safety standards.As a result, you can have total assurance when dealing with us as a gasket supplier in Australia.

Industrial Gaskets & Seals Use and Functionality

A gasket is simply an elastomeric component that covers the point where two surfaces meet. Its main function is to prevent leaks and, to do this, it must be compressed so that it fills any irregularities and creates a tight and impenetrable seal. Gaskets are also used to protect contents and to prevent moving parts from creating friction when they rub against hard surfaces.

For a perfect outcome, industrial gaskets and seals have to be manufactured from materials that will deform under pressure. Common ones used are Nitrile, Ethylene Propylene (EPDM), Silicone and Neoprene. Some gaskets are manufactured from a mixture of metals and softer materials, so they are extremely durable as well as flexible. When making a gasket, we choose the most suitable material for a particular application based on specific needs. These can include its:

- flexibility, so that it deforms to fill any irregularities in component surfaces and forms a perfect seal that prevents any leaks

- anti-vibration and noise reduction characteristics

- ability to protect moving parts from damage

- resistance to extreme temperatures, pressure and chemicals.

As a result of their many forms and characteristics, industrial gaskets and sealents are used in a variety of equipment such as pumps and electrical equipment, and in door seals. Their adaptability means they’re widely used in many industries such as pharmaceuticals and food processing where high hygiene standards are essential, deep sea operations that depend on reliability and aerospace where precision is crucial.

Bespoke Industrial Seals & Gasket Products for Specific Needs

Our experience and knowledge in providing industrial seals and gaskets and many other rubber engineering and Australian injection moulding components across a broad range of industries mean we can provide exactly the products you need in the required quantities and quickly, so your project isn’t delayed. We can supply standard products for basic needs but specialise in designing and manufacturing bespoke parts that are exactly right for your application.

We understand the need for prompt delivery but also the importance of supplying components like rubber mouldings that are of the highest quality and will do the job required of them without fail. So we use the best and latest technology and employ the most skilled and highly trained staff. Most of all, we use exhaustive quality control procedures for everything we make and provide excellent customer service so you can be assured you’ll get exactly what you need when you need it. Get in touch if you require more information and we’ll be delighted to help. Read Less